Specs

Location: Seattle

Square footage: 1,800 + 650 (ADU)

Year of completion: 2004

Architect: Ted Granger

Green Features

- Advanced framing

- Extensive use of salvaged materials

- Full-line jobsite recycling

- Heat recovery ventilator (HRV)

- 7,000-gallon cistern

- Extensive education program for subcontractors and public

- Annual water savings of approximately 115,340 gallons

- 9” thick double-framed 2x4 walls insulated with cellulose to R-33

- R-48 SIPs roof 12" thick

- Blower door test at .14 ACH at natural pressure

- Vacuum tube solar water collector

- Fly ash concrete mix

Description

Built Green's First 5-Star Project

For this project we de-constructed an existing home and built a new energy-efficient and healthy home. This home was Built Green's first 5-Star project. The Sensible House project was about building a home that is affordable, attractive, comfortable, functional, healthy, and environmentally friendly without compromise. The idea for this home is to demonstrate that an environmentally friendly home offers all the comforts, benefits, and amenities of traditional homes, but with added features that protect human health and our quality of life. From the beginning the goal was to push our limits on green building practices and products. Thus the Sensible House began on a small lot in Northeast Seattle.

Deconstruction

We elected to deconstruct the existing 1948 “shotgun” style house instead of remodeling to most effectively reach our energy and healthy house goals affordably. The ReStore salvaged for reuse virtually all materials prior to construction. Many of the materials were reused in the Sensible House project; other materials were salvaged for resale. The remaining materials were sorted for recycling. Very little material was sent to the landfill.

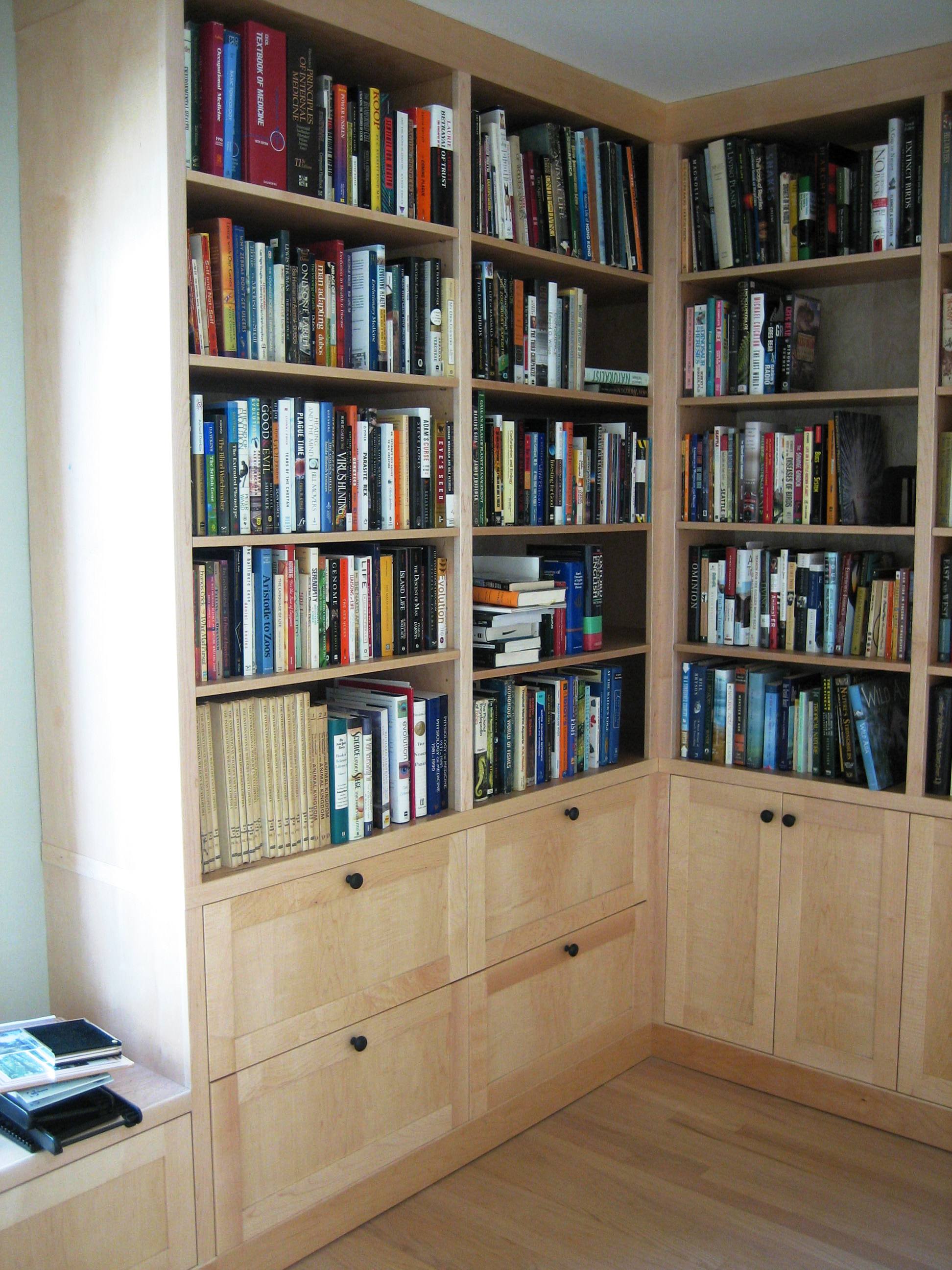

Just the Right Size

The new 1,800-square-foot main unit, accompanied by a 650-square-foot accessory dwelling unit (ADU), was designed with “not so big house” principles tweaked into what we call “just the right size” house. Care was taken in the design of the house, to build only rooms the owners would use day-to-day, and making those rooms a functional size and no bigger. We also used design to make spaces “feel good” to enhance the owners' wellness by creating sunny spaces, gathering places, and places that connect the indoors and the outdoors.

Learn more at www.sensiblehouse.org

Press

JLC: Profiles in Green